Cowhide / Kip leather / Amami Oshima mud-dyed leather / Line-dyed

Cowhide / Kip leather / Amami Oshima mud-dyed leather / Line-dyed

Mud dyeing is a dyeing method used in the world-famous traditional industry of Amami, a part of Kagoshima Prefecture, "Authentic Oshima Tsumugi," with a history of 1,300 years. Mud-dyed leather is leather that is dyed a dark brown color using dye made by boiling and naturally fermenting chips of the techi tree (scientific name: wheel plum) that grows naturally on the island, and mud that is rich in iron and has small, round particles that are only found in certain areas of Amami. You can enjoy the miraculous patterns and unique individuality, such as deep black and brown hues and tie-dyed patterns that are different from chemical dyes.

[Line aperture]

The leather is pleated evenly (of the same width) and folded accordion-like, and then rubber or string is wrapped around it and dyed to create a accordion-like pattern.A unique continuous linear design is created by the color of the original leather material, the brown color of the techi wood, and the black-brown color of the mud.

Mud dyeing creates miraculous patterns

Amami Oshima Mud Dyeing

Mud dyeing is a dyeing method used for the world-famous traditional industry of Amami, which belongs to Kagoshima Prefecture, "Authentic Oshima Tsumugi," with a history of 1,300 years. Mud-dyed leather is leather that is dyed a dark brown color using a dye made by boiling and naturally fermenting chips of the "techi" tree (scientific name: wheel plum) that grows naturally on the island, and mud that is rich in iron and has small, round particles that are only found in certain areas of Amami. Mud-dyed leather, which was created over the years to explore new possibilities for dyeing leather while preserving traditional craft techniques, expresses miraculous patterns and unique individuality, such as deep black and brown hues and shibori patterns that are different from chemical dyes.

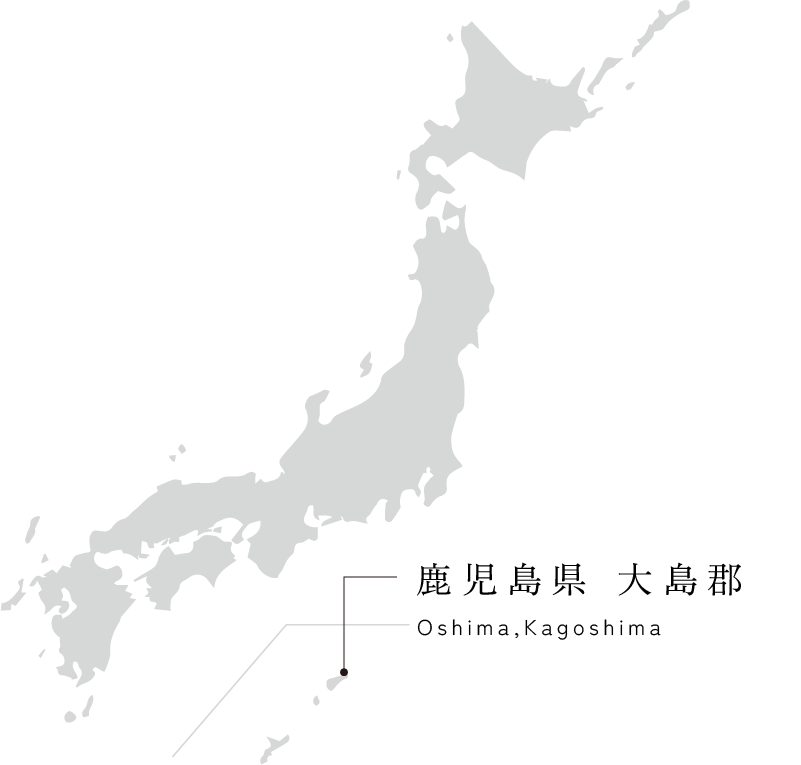

Amami Oshima and Mud Dyeing

Kagoshima Prefecture/Amami Oshima is a place where untouched nature remains.

Mud dyeing has been practiced for a long time on this island, located close to the main island of Okinawa. All processes are carried out by hand by artisans on the island, and mud dyeing is one of the island's important industries.

A tannic red wine grown in sea breeze and fertile soil.

Mud dyeing is based on plant dyeing, which uses the techi tree (wheel plum) that grows naturally on the island. The techi tree harvested on Amami Oshima contains a high concentration of tannic acid due to the strong sea breeze and fertile soil, making it extremely suitable for dyeing.

*The red part in the center is tannin.

*Because techi trees are cut down leaving about 1m of their trunk,

After 7-8 years it can be used again as a dye.

The deep red soil of Amami Oshima

The mud from Amami Oshima used in mud dyeing has characteristics such as fine particles, roundness, and abundance of naturally occurring iron. Furthermore, because the soil is red clay, which is rich in naturally occurring iron, it reacts with the abundant dyed tannins, changing the color from brown to blackish brown. It is this iron mordant that expresses the unique colors of Amami. The ground in areas such as rice paddies is dug to create depressions, and the surrounding mud is poured in to increase the concentration of iron. The fine particles are the result of the action of microorganisms; the rice paddies used for dyeing are located at the foot of steep mountains, and mineral-rich water flows in from the mountains, providing food for the microorganisms, which become active.

Repeatedly rub with hands

To ensure that the mud-dyed leather is dyed in the desired pattern, each piece is tied by hand. With years of experience, the craftsmen pinch, fold, and tie the pleats in different ways depending on the dyeing pattern. This manual work is what gives the leather its unique personality and creates miraculous patterns.

Binding and folding by hand

The leather to be dyed is hand-tied one by one to match the desired pattern. With years of experience, the craftsman pinches, folds, and ties the pleats, and changes the tying method depending on the dyeing pattern. It is this manual work that expresses unique individuality and brings out the miraculous patterns.

Indigo dye craftsman

Junichi Higo

In around 1965, he started working as an apprentice at a mud dyeing factory in Ariya. He has won numerous awards in the dyeing category at authentic Amami Oshima Tsumugi contests. In addition to dyeing Oshima Tsumugi, he also handles requests for apparel dyeing and is active as a mud dyeing model. He is a pioneer of mud dyeing.

Featured products

-

Cow leather / Hand-painted art dye / Red

AST-05Regular price ¥19,457 JPYRegular priceUnit price per -

Cowhide / Kip leather / botanical leather® Sakura dye / Somei Yoshino

BSY-01Regular price ¥42,662 JPYRegular priceUnit price per -

Cow leather / Hand-painted art dye / Green

AST-07Regular price ¥25,168 JPYRegular priceUnit price per -

Cow leather / Hand-painted art dye / Blue

AST-06Regular price ¥27,394 JPYRegular priceUnit price per

- Choosing a selection results in a full page refresh.

- Opens in a new window.