Card case / botanical leather® indigo dye / spotted / cowhide

Card case / botanical leather® indigo dye / spotted / cowhide

Indigo dyeing was introduced from China in ancient times, and was popular among the common people in the Edo period. As it has a strong antibacterial effect, dyed clothes are also effective in preventing skin diseases and poisonous insects. The indigo plant, which is the raw material, comes in various varieties such as Kojoko, Hyakukan, and Senbon, and is currently cultivated in Tokushima, Miyazaki, Hokkaido, etc., but production is decreasing year by year. At "te saho", we mainly use fermented indigo plant of Kojoko from Tokushima, which has been praised as the finest since the Edo period, and dye it in layers using the vat dyeing method.

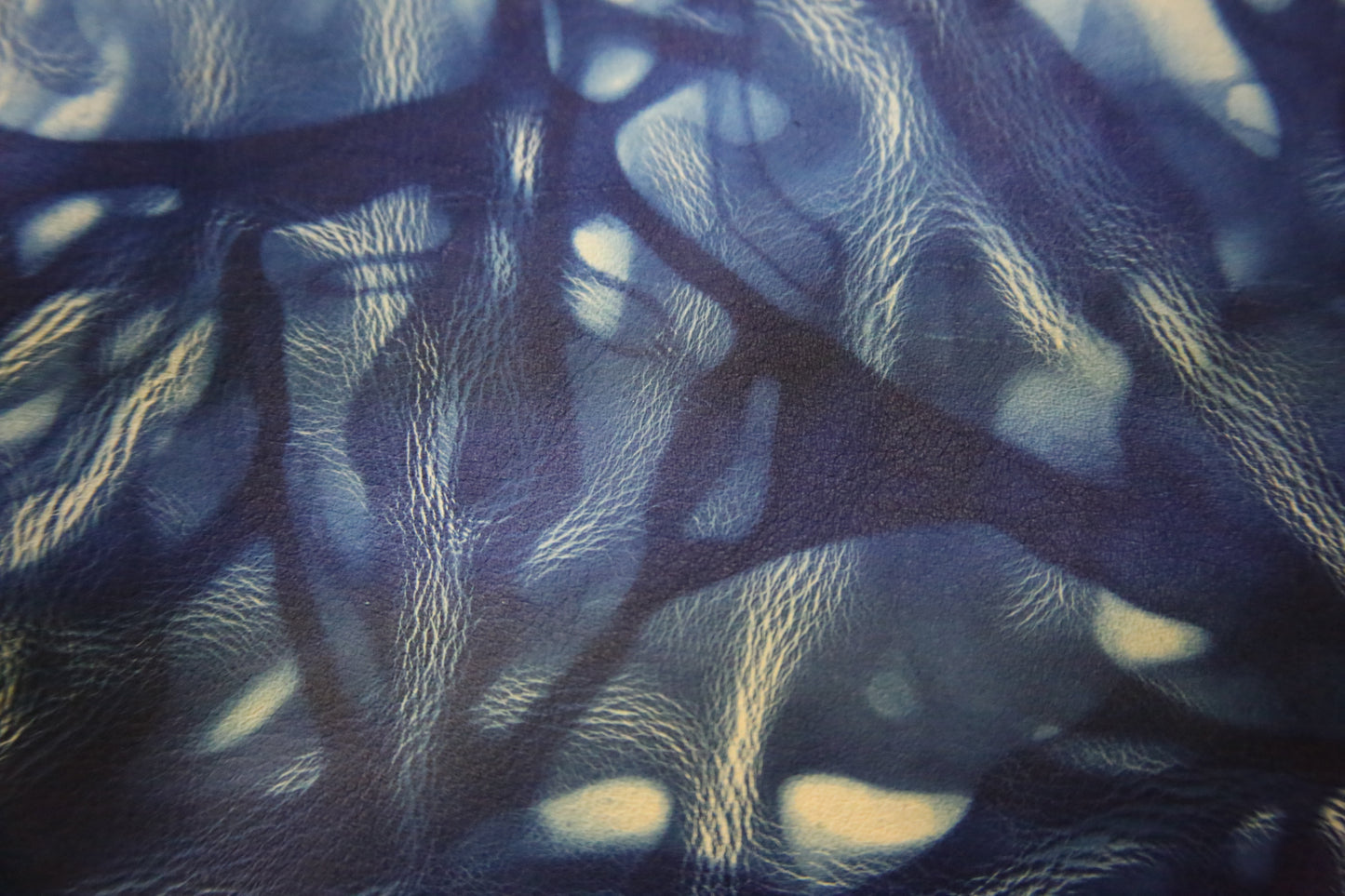

[Mottled dyeing]

This is a traditional technique in which the leather is soaked in water to soften it, then squeezed by hand. Repeated dyeing creates complex patterns, and the thinner the material, the finer and more delicate the patterns will be.

A multi-purpose card case made entirely of leather. Since it is made entirely of leather, it fits neatly into your pocket. It opens and closes with a flap, and can hold about 5 cards, about 10 business cards (varies depending on material), and about 10 to 15 coins. You can enjoy it according to your needs.

|

This product is unique due to individual differences in dyeing, so it may not be the same as the product in the image. Please note that products with patterns may be rendered differently from the pattern in the image. |

The color "Japan Blue"

Indigo dye

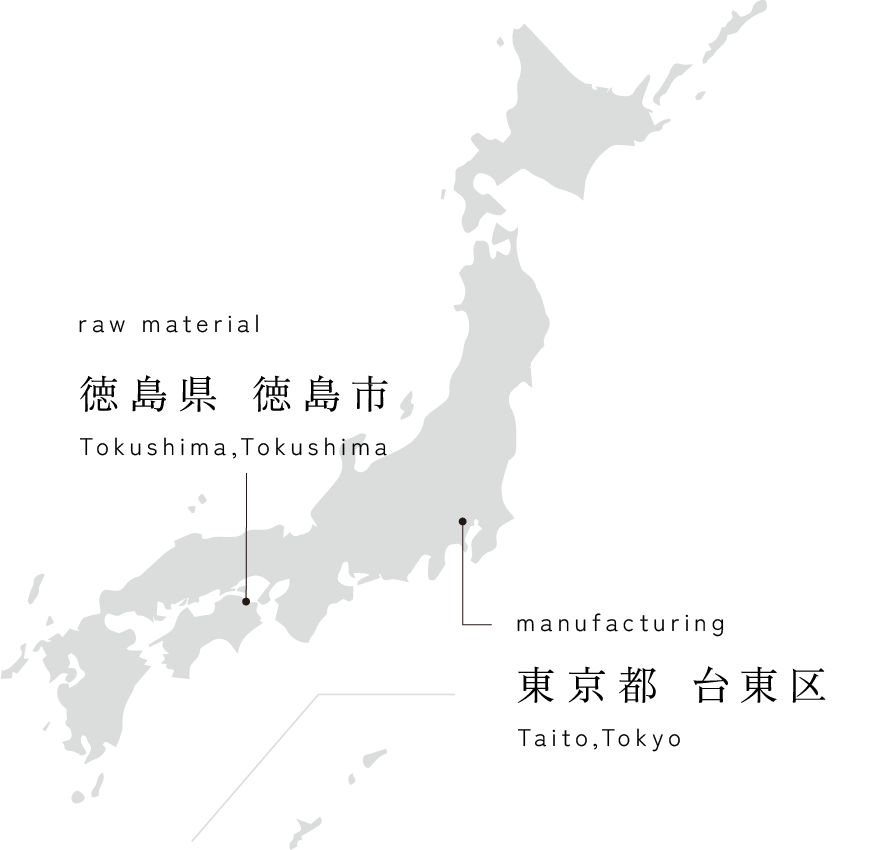

Indigo dyeing is done by fermenting and dyeing using "sukumo" made from Polygonum indigo in Tokushima Prefecture. Indigo fermentation liquid is highly alkaline, and leather is weak to alkaline, so a special indigo fermentation liquid with weaker alkalinity is made for leather and dyeing. This liquid spoils easily and has a pale color, so it must be dyed with care, and it takes more time and effort than indigo dyeing fabric. In recent years, indigo-dyed leather dyed with chrome tanning has become more common, but tannin-tanned leather has low resistance to alkali and water, making it very difficult to dye, so tannin-tanned indigo-dyed leather is very valuable. Sukumo is made by adding water to dried indigo leaves and fermenting them. The harvested indigo is dried and crushed by hand while kneading. At this time, stems and debris are removed, leaving only the leaves. The crushed leaves are mixed well with water and fermented, matured for about three months, and dried in the shade. The pH of the resulting indigo is adjusted to an alkaline level, and the process of fermenting it is called "aidate." Through these various intricate craftsmanship steps, a deep, vibrant indigo color is achieved.

Indigo from Tokushima Prefecture has been popular since the Edo period

Indigo dyeing was introduced from China in ancient times, and was popular among the common people in the Edo period. It has a strong antibacterial effect, and dyed clothes were used to prevent skin diseases and poisonous insects. There are various varieties such as Kojoko, Hyakukan, and Senbon, and it is currently grown in Tokushima, Miyazaki, Hokkaido, etc., but production is decreasing year by year. At "te saho", we mainly use fermented indigo plant of Kojoko from Tokushima, which has been praised as the finest since the Edo period, and we ferment and dye it.

Indigo dye

Indigo plants contain a substance called indican. When the plant's cells are destroyed, the enzymes in the leaves cause the indican to oxidize easily, and when it comes into contact with air, it oxidizes and becomes the indigo pigment that gives the plant its indigo color.

Indigo dye is a pigment that is insoluble in water. This insoluble indigo dye is made soluble in an alkaline aqueous solution through an oxidation-reduction reaction, which is called "indigo dye-making." Indigo dye-making using the action of microorganisms is called "fermentation dye-making," while indigo dye-making using chemicals is called "chemical dye-making." The alkaline aqueous solution used in the indigo dye-making process is absorbed onto the leather and then oxidized again within the fibers, causing the indigo dye to develop its indigo color.

The difficulty of indigo dyeing leather

Indigo dyeing is done in a workshop in Taito, Tokyo, using "sukumo" from Tokushima Prefecture, which is made from Japanese knotweed. Normally, indigo fermentation liquid is highly alkaline, and leather is weak to alkaline, so a special indigo fermentation liquid with a weaker alkali is made and dyed. Chrome-tanned indigo-dyed leather is now becoming available, but tannin-tanned leather has poor resistance to alkaline and water, making it very difficult to dye and a valuable indigo-dyed leather.

Adjusting the color of a once-in-a-lifetime encounter

"Sukumo" is made by adding water to dried indigo leaves and fermenting them. The harvested indigo is dried and crushed by hand while being rubbed. At this time, stems and debris are removed, leaving only the leaves. The crushed leaves are mixed well with water and fermented. It is left to mature for about a month and then dried in the shade. The resulting sukumo is mixed with lye and lime to adjust the pH to an alkaline level, and wheat bran, which acts as nutrients for the microorganisms, as well as sake and glucose, are added, and the indigo dye solution is made by fermenting.

Environmentally friendly dyeing frequency

The intensity of the indigo dye color changes depending on the number of times it is dyed, the weather of the day, and other environmental factors. It is dyed repeatedly about 15 times with indigo blue and about 25 times with indigo blue.

Dyeing

Masato Komuro

Born in Fukuoka in 1983, he lives in Tokyo. He moved to Akizuki, Asakura City, Fukuoka Prefecture, where he was exposed to plant dyeing at his family's plant dyeing studio (Kobo Yumezaiku). He majored in dyeing and weaving at the Department of Crafts, Faculty of Fine Arts, Tokyo University of the Arts. While studying traditional techniques, he also explored new technical expressions such as plant dyeing leather. In 2007, he introduced whole garment knitting and mastered the techniques. In 2008, he started his own knitwear brand, "MAITO". In 2010, he established Might Design Works Co., Ltd. In the same year, he opened a directly managed store at 2k540 in Ueno, Taito Ward, Tokyo. In 2012, he opened an atelier shop in Kuramae, Taito Ward, Tokyo.

Featured products

-

Cow leather / Hand-painted art dye / Red

AST-05Regular price ¥19,456 JPYRegular priceUnit price per -

Card case / botanical leather® Sakura dye / Mountain cherry / Cowhide

BYZ-C-01Regular price ¥12,100 JPYRegular priceUnit price per -

Cowhide / Kip leather / botanical leather® Sakura dye / Somei Yoshino

BSY-01Regular price ¥42,662 JPYRegular priceUnit price per -

Card case / botanical leather® Yakusugi dye / cowhide

BYS-C-01Regular price ¥12,100 JPYRegular priceUnit price per

- Choosing a selection results in a full page refresh.

- Opens in a new window.